Aluminum Foundry strategies shown in a helpful post

Discover the Function of Metal Shops in Modern Production Processes

Metal foundries are indispensable to the production landscape, transforming resources right into crucial parts for different fields. Their innovative strategies, consisting of 3D printing and CAD, enable the production of complex get rid of marginal waste. On top of that, foundries are increasingly adopting sustainable practices to enhance their environmental impact. Comprehending the full extent of these procedures discloses their considerable influence on markets like auto and aerospace, motivating a closer exam of their advancing duty in modern-day production.

The Essential Functions of Steel Shops

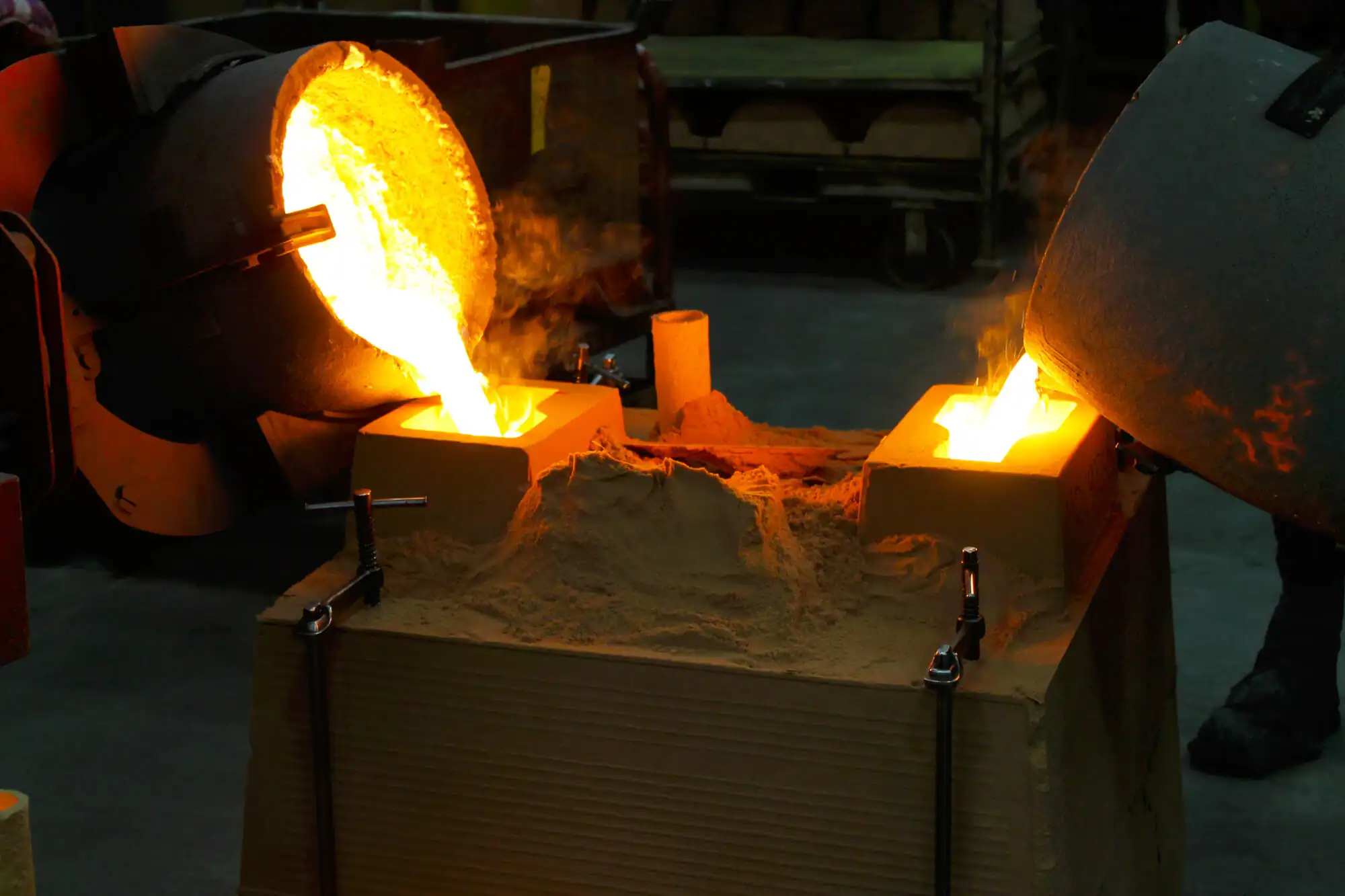

Metal foundries play an essential role in the production field by changing basic materials right into useful metal products via different procedures (Aluminum Foundry). These centers are essential for generating parts made use of in many markets, including automobile, aerospace, and building and construction. Factories mainly concentrate on melting steel alloys and putting them into mold and mildews to create details shapes, a procedure referred to as casting

Factories provide customized solutions, such as warm therapy, which boosts the mechanical residential or commercial properties of metal products. By promoting these crucial functions, steel foundries add greatly to the overall effectiveness and technology within the manufacturing landscape, making it possible for the manufacturing of a wide variety of steel items.

Advanced Technologies in Metal Spreading

As the manufacturing industry develops, advanced modern technologies in metal spreading are reshaping the landscape of production. Developments such as 3D printing and computer-aided layout (CAD) have actually significantly improved the effectiveness and precision of casting processes. These modern technologies allow shops to produce complex geometries that were previously tough or difficult to attain, thereby decreasing material waste and enhancing overall quality.

Additionally, automation and robotics have structured operations, reducing manual labor while enhancing manufacturing rate. Integrating sophisticated simulation software application enables factories to optimize casting styles and predict possible flaws before production, even more improving dependability.

The advent of clever production systems, integrating the Web of Things (IoT), facilitates real-time monitoring of procedures, ensuring better control over production parameters. These technical innovations not just drive cost-effectiveness however also placement steel shops at the leading edge of modern production, enabling them to satisfy the developing needs of various markets.

Sustainability Practices in Foundries

While the manufacturing sector deals with increasing stress to adopt ecologically accountable methods, shops are actively applying sustainability procedures to lower their environmental impact. Many factories have actually accepted recycling efforts, using scrap steel and other products to lessen waste and save sources. Advanced innovations, such as energy-efficient heaters and automated processes, even more enhance their commitment to sustainability.

Shops are also concentrating on boosting and lowering exhausts air quality by embracing cleaner production techniques. Making use of eco-friendly binders and finishes has actually obtained grip, lowering hazardous by-products in the spreading process. Furthermore, water conservation procedures are being applied, with closed-loop systems lowering freshwater consumption and wastewater discharge.

The Effect of Factories on Numerous Industries

Although often neglected, factories play a necessary duty in providing necessary components across a diverse range of industries. These facilities are crucial in creating steel castings used in automotive, building, machinery, and aerospace sectors. In the vehicle industry, foundries supply engine blocks, transmission situations, and other important elements, ensuring lorries operate successfully. Aerospace depends heavily on precision-cast my sources components that fulfill rigid safety and security requirements, while construction business depend upon strong and sturdy steel products for infrastructure tasks.

Factories add to the power sector by making components for power generation devices, including generators and turbines. Their versatility prolongs to durable goods, where cast metal components improve item performance and sturdiness. By supporting numerous markets, shops not only boost manufacturing capacities yet also drive advancement and technological innovations, emphasizing their considerable influence on the international economic climate.

Future Fads in Metal Factory Procedures

Progressing and emerging innovations market needs are forming the future landscape of metal factory operations. Automation and robotics are significantly being incorporated to enhance effectiveness and minimize labor expenses. Smart foundries are leveraging information analytics and the Internet of Points (IoT) to monitor production processes in real-time, assisting in anticipating maintenance and lessening downtime.

Sustainability is also coming to be a centerpiece, with shops adopting greener practices by recycling materials and reducing energy consumption. Advanced materials, such as lightweight alloys and composites, are gaining grip, driven by sectors such as aerospace and automobile seeking enhanced performance.

Moreover, additive manufacturing is emerging as a corresponding modern technology, allowing the manufacturing of intricate geometries that typical techniques can not achieve. As digitalization progresses, steel foundries are anticipated to adopt more versatile manufacturing systems, permitting customized, on-demand production options. These patterns indicate a transformative shift, positioning steel foundries for a vibrant future in manufacturing.

Regularly Asked Questions

What Materials Are Generally Utilized in Metal Foundries?

Steel factories frequently utilize products such as iron, aluminum, bronze, brass, and different alloys. These products are chosen for their unique buildings, enabling the production of varied elements customized for details applications in numerous markets.

Just How Do Foundries Guarantee Quality Assurance in Manufacturing?

Factories implement stringent quality assurance measures, consisting of material assessments, procedure surveillance, and testing of completed products. They make use of advanced modern technologies and requirements to assure uniformity, adherence, and integrity to specifications throughout the manufacturing procedure.

What Precaution Are Executed in Steel Shops?

Steel shops implement safety measures such as individual safety devices, air flow systems, routine security training, and emergency procedures. These techniques aim to reduce risks connected with high temperatures, harmful fumes, and heavy machinery operations.

How much time Does the Steel Casting Process Normally Take?

The steel casting process normally takes several hours to days, depending on factors such as the complexity of the layout, kind of metal made use of, and cooling down times needed for the particular casting technique utilized.

What Are the Job Opportunities in Metal Foundries?

Profession chances in metal foundries include roles such as foundry technicians, metallurgists, top quality control examiners, device drivers, and production supervisors - Metal Casting. These positions use varied paths in production, engineering, and skilled trades within the sector

Metal factories are important to the manufacturing landscape, Check Out Your URL converting raw materials right into vital elements for various sectors. Steel shops play an essential function in the production industry by changing raw materials into try these out functional steel products with different processes. In addition to spreading, steel factories also involve in processes such as machining, where excess product is removed to achieve exact requirements. As digitalization proceeds, metal foundries are anticipated to embrace even more versatile production systems, enabling for tailored, on-demand manufacturing services. Occupation possibilities in steel foundries consist of duties such as shop service technicians, metallurgists, quality control examiners, equipment drivers, and production managers.